Showing all 3 results

12 Volt Dc Oil Pump

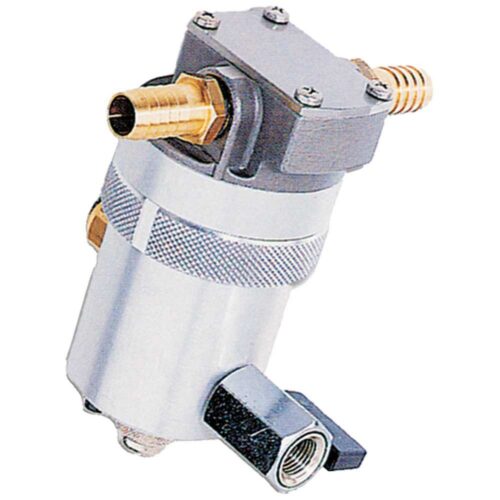

240 Volt High Flow Gear Oil Pump – SKU: DITI17320140

240 Volt High Volume Gear Oil Pump

Electric Oil Transfer Pumps

Efficient fluid management is crucial for any workshop, industrial facility or fleet operation. One of the critical components in achieving this efficiency is the use of high-quality oil transfer pumps. At ProDepot, you can explore a variety of oil transfer pumps designed to facilitate the smooth and accurate transfer of oil, ensuring minimal waste and optimal performance of machinery and vehicles.

The role of this mechanical device is to move oil from one container to another. These pumps are commonly used in workshops, industrial settings and automotive applications to ensure the efficient and clean transfer of oil. They help reduce manual labour, prevent spills and maintain a clean work environment.

Key Features of Oil Transfer Pump Electric

Our oil transfer pump electric significantly enhances the efficiency of oil transfer processes. Electric pumps, in particular, offer fast and consistent performance, reducing downtime and increasing productivity. Using a transfer pump ensures precise control over the amount of oil being transferred. This precision helps maintain the correct oil levels in machinery and vehicles, which is crucial for optimal performance.

Another advantage of using our transfer pump is that it reduces the risk of spills and accidents, promoting a safer work environment. They are designed to handle oil securely, preventing leaks and minimising the risk of fire hazards.

Key Features of Oil Transfer Pumps:

Durable Construction

- High-quality engine oil transfer pumps are built from robust materials that can withstand the harsh conditions of industrial and automotive environments. This durability ensures long-term reliability and performance.

Ease of Use

- Modern oil transfer pumps are designed with user-friendly features, such as ergonomic handles, clear control panels, and easy installation procedures. This makes them accessible to operators of all skill levels.

Versatility

- Many oil transfer pumps are compatible with various types of oil, including engine oil, hydraulic oil and transmission fluid. This versatility makes them a valuable addition to any workshop or industrial facility.

High Flow Rate

- Electric oil transfer pumps offer a high flow rate, enabling the rapid transfer of large volumes of oil. This is particularly beneficial in busy environments where time is of the essence.

Explore wide range of Tool Equipment Products:

Frequently Asked Questions

Can I use the same oil transfer pump for different types of oils?

In many cases, you can use the same oil transfer pump for different types of oils, such as engine oil, transmission fluid and hydraulic oil. However, checking the pump's specifications and compatibility with the specific oils you intend to use is essential. Some pumps may have limitations on the viscosity range or chemical compatibility of the oils they can handle. Additionally, if you plan to use the same pump for different types of oils, it's crucial to thoroughly clean the pump and hoses between uses to avoid cross-contamination.

How do I select the proper engine oil transfer pump for my vehicle?

When choosing an engine oil transfer pump for your vehicle, consider factors such as the pump's flow rate, compatibility with your engine oil type, and the size of your vehicle's oil reservoir. The pump's flow rate should be sufficient to efficiently transfer the oil without causing excessive pressure or heat buildup. Ensure that the pump materials are compatible with the specific type of engine oil you use, as some oils may degrade certain materials over time.

What safety precautions should I take when using an oil transfer pump electric model?

Always read and follow the manufacturer's instructions and safety guidelines. Ensure the pump is properly grounded and connected to a power source with the correct voltage and amperage. Avoid using the pump in wet environments, which can increase the risk of electrical shock. When handling oils and operating the pump, wear appropriate personal protective equipment, such as gloves and safety glasses. Regularly inspect the pump, hoses, and connections for signs of wear, damage or leaks, and replace any damaged components promptly.